Exploring the Versatile Applications and Unique Features of Various Best Laser Marking Machines

In today's fast-paced manufacturing landscape, the demand for precision and efficiency is paramount, making the Laser Marking Machine an indispensable tool for various industries. This technology not only offers versatile applications—ranging from engraving intricate designs on metal surfaces to marking barcodes on packaging—but also comes with unique features that enhance productivity and product differentiation. However, choosing the right laser marking machine involves understanding its operational benefits, the advantages of after-sales service, and maintenance costs associated with these sophisticated devices. In this blog, we will explore the various applications and standout features of the best laser marking machines available in the market, while also providing insights into their upkeep and the value of professional support after purchase, ensuring that your investment remains sound and continues to deliver exceptional results.

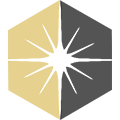

Understanding the Fundamentals of Laser Marking Machines: Types and Technologies

Laser marking machines are essential tools across various industries, offering precise and efficient marking solutions. Understanding the fundamentals of these machines involves recognizing the different types, including fiber, CO2, and UV lasers, each designed for specific materials and applications. According to a recent market report by Research and Markets, the global laser marking equipment market is projected to reach $5.42 billion by 2026, underscoring the growing demand for these technologies.

Laser marking machines are essential tools across various industries, offering precise and efficient marking solutions. Understanding the fundamentals of these machines involves recognizing the different types, including fiber, CO2, and UV lasers, each designed for specific materials and applications. According to a recent market report by Research and Markets, the global laser marking equipment market is projected to reach $5.42 billion by 2026, underscoring the growing demand for these technologies.

When selecting a laser marking machine, consider the material you will be working with. For instance, fiber lasers are highly effective for metals, offering high engraving speeds and depth control, while CO2 lasers excel in marking organic materials such as wood and plastics. Tip: Always evaluate the power and wavelength of the laser to ensure compatibility with your intended materials, as this significantly influences the quality and durability of the markings.

Moreover, advancements in technology, such as the integration of AI and automation, are enhancing the capabilities of laser marking machines. This not only increases productivity but also improves the precision of markings. Tip: Stay updated with emerging technologies to leverage the most efficient laser marking solutions for your business, as these innovations can lead to substantial cost savings and improved operational efficiency.

Key Features to Look for When Choosing a Laser Marking Machine

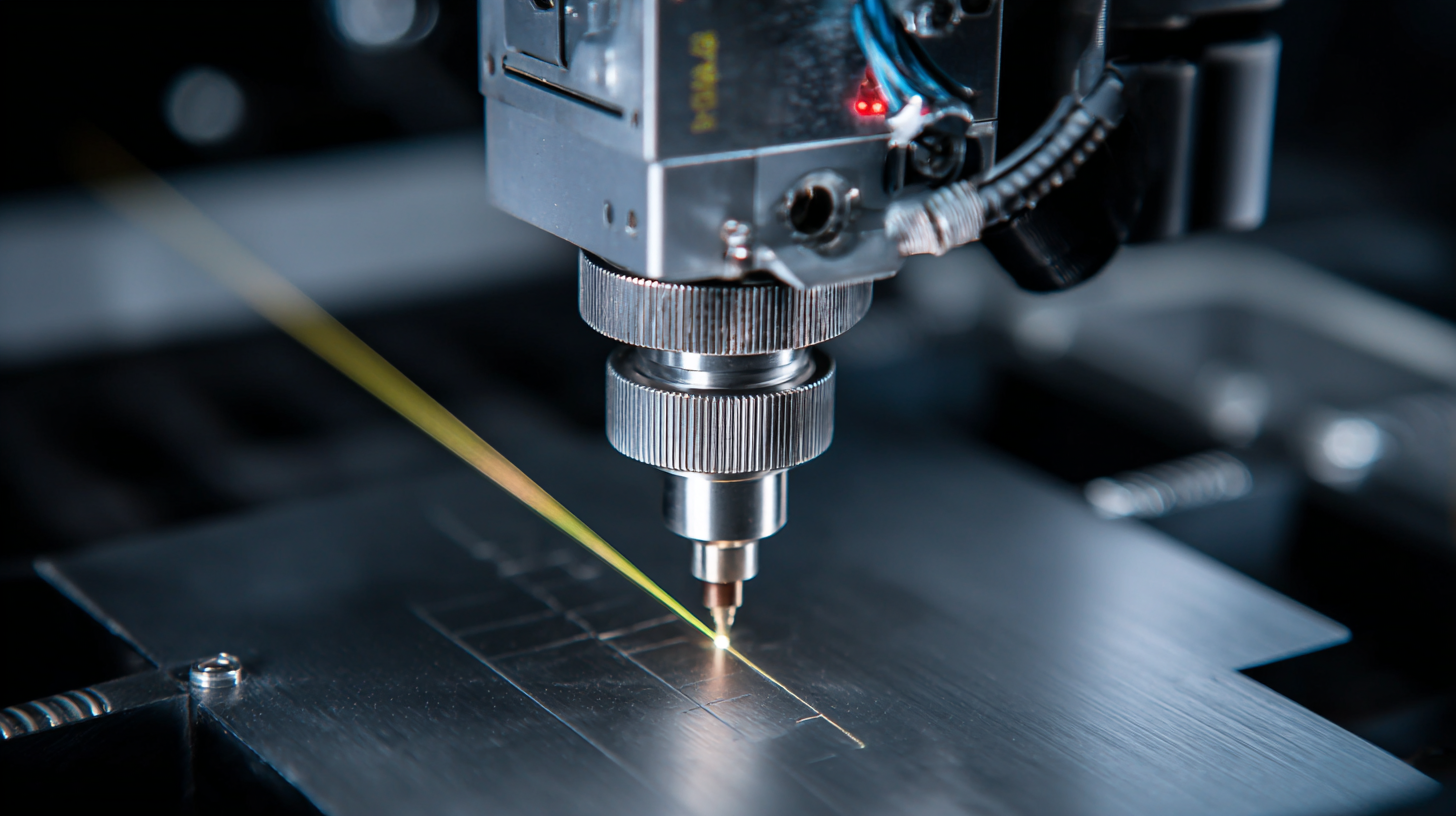

When selecting a laser marking machine, several key features should be at the forefront of your decision-making process. First and foremost, the power of the laser plays a critical role in determining the machine's versatility and efficiency. A higher wattage enables the machine to mark a wider range of materials with greater depth and clarity, making it essential for users who require precision in their markings, especially in industrial applications.

Additionally, the type of laser technology—whether CO2, fiber, or diode—can significantly impact the quality and speed of the marking process. Each technology offers unique advantages catering to different materials and applications.

Another essential aspect to consider is the software compatibility of the marking machine. The ability to integrate with design software and support various file formats enhances the user experience and workflow efficiency. Furthermore, features such as the machine's engraving speed, resolution, and size of the marking area should align with your specific needs. A machine equipped with advanced cooling systems and robust construction ensures durability and consistent performance over time. Understanding these key factors will empower users to make informed choices, ultimately leading to enhanced productivity and quality in their marking tasks.

Comparative Analysis of Fiber, CO2, and UV Laser Marking Machines

When it comes to laser marking machines, the choice between fiber, CO2, and UV lasers can significantly impact the quality and type of marking achieved. Fiber laser marking machines are renowned for their speed and precision, making them an ideal choice for metals and other hard materials. Their ability to produce high-contrast markings with fine detail makes them favored in industries such as automotive and aerospace, where durability and readability are paramount.

On the other hand, CO2 laser marking machines excel in cutting and engraving non-metal materials like wood, glass, and plastics. They produce smooth and clean markings, which are essential for applications requiring intricate designs or branding elements. CO2 lasers are often preferred in industries like packaging and textiles, where versatility and the ability to mark a variety of surfaces are needed.

UV laser marking machines stand out for their ability to mark sensitive materials without causing thermal damage. These machines utilize a shorter wavelength that enables them to interact with the material's surface at a microscopic level. This makes UV lasers particularly suitable for marking medical devices, electronics, and certain plastics, where preserving the integrity of the material is crucial. The comparative analysis of these laser types highlights their unique features, allowing businesses to select the most suitable option for their specific marking needs.

Comparative Analysis of Laser Marking Machine Types

Innovative Applications of Laser Marking in Various Industries

Laser marking technology has revolutionized various industries by offering innovative applications that enhance product identification, traceability, and branding. In manufacturing, laser marking is utilized for precise engraving of serial numbers and barcodes directly onto components, ensuring durability and visibility throughout the product's lifecycle. This permanence reduces the risk of errors during assembly and allows for easy tracking, especially in sectors like automotive and aerospace where compliance is critical.

Additionally, the food and beverage industry is leveraging laser marking to provide clear, reliable information on packaging. Laser marking can produce high-resolution images and text on labels without the use of ink or adhesives, thus avoiding potential contamination. Moreover, this technology enables brands to include intricate designs and logos, which not only boosts product aesthetics but also helps meet regulations for ingredient listings and expiration dates. As businesses prioritize sustainability, laser marking machines emerge as an eco-friendly solution, reducing waste while maintaining high production standards.

Tips for Maintaining and Optimizing Laser Marking Machine Performance

When it comes to laser marking machines, maintaining optimal performance is crucial for achieving high-quality results. Regular maintenance not only extends the lifespan of the machine but also ensures consistent marking precision. Users should focus on cleaning the optics and checking the alignment of the laser beam. Dust and debris can significantly affect the marking quality, leading to subpar results. Additionally, regular calibration of the machine is essential. This involves checking the software settings and ensuring that the speed, power, and frequency parameters are fine-tuned according to the material being marked.

In an era where advancements in laser technology intersect with other fields such as artificial intelligence and 3D printing, it's vital to stay informed about emerging trends. For instance, the integration of AI into laser marking processes can optimize workflow efficiency, adapting operations based on real-time feedback. Innovations like the application of laser-induced texturing not only enhance the functionality of products but also promote sustainable practices. By implementing these technologies, businesses can elevate their manufacturing processes, reduce waste, and increase overall efficiency in their laser marking applications.