Ultimate Guide to Selecting the Best Alpha Winding Machine for Your Production Needs

In the fast-evolving manufacturing landscape, selecting the right equipment is pivotal for optimizing production efficiency and product quality. The Alpha Winding Machine has gained considerable attention among industry professionals, especially given its ability to enhance winding precision and reduce operational downtime. According to a recent market research report by Mordor Intelligence, the global winding machine market is projected to grow at a CAGR of 5.6% from 2021 to 2026, highlighting the increasing reliance on advanced winding technologies in various sectors. As businesses look to streamline their production processes, understanding the key features and benefits of different Alpha Winding Machines becomes essential. This ultimate guide will explore the top strategies for selecting the best machine tailored to your unique production needs, ensuring your operations remain competitive in an ever-demanding market.

Key Factors to Consider When Choosing an Alpha Winding Machine

When selecting the best Alpha winding machine for your production needs, several key factors should be carefully considered to ensure optimal performance and efficiency. First and foremost, assess the machine’s capacity and compatibility with your specific winding application. Different machines offer varying spool sizes and winding speeds, so it's crucial to choose one that aligns with your production requirements. Additionally, contemplate the machine's flexibility; a model that can accommodate various coil configurations or wire types may provide better utility and adaptability in changing production demands.

Another important factor is the machine’s ease of use and maintenance. Look for features that simplify operations, such as intuitive controls, automatic thread tensioning, and user-friendly interfaces. Machines that require less downtime for maintenance not only improve productivity but also enhance the overall efficiency of your winding processes. Lastly, consider the level of technical support and warranties offered by the manufacturer. A reliable support system can make a significant difference, ensuring that any issues can be addressed swiftly, keeping your production on track and minimizing disruptions. Choose wisely to optimize your investment in an Alpha winding machine.

Understanding Different Types of Alpha Winding Machines Available

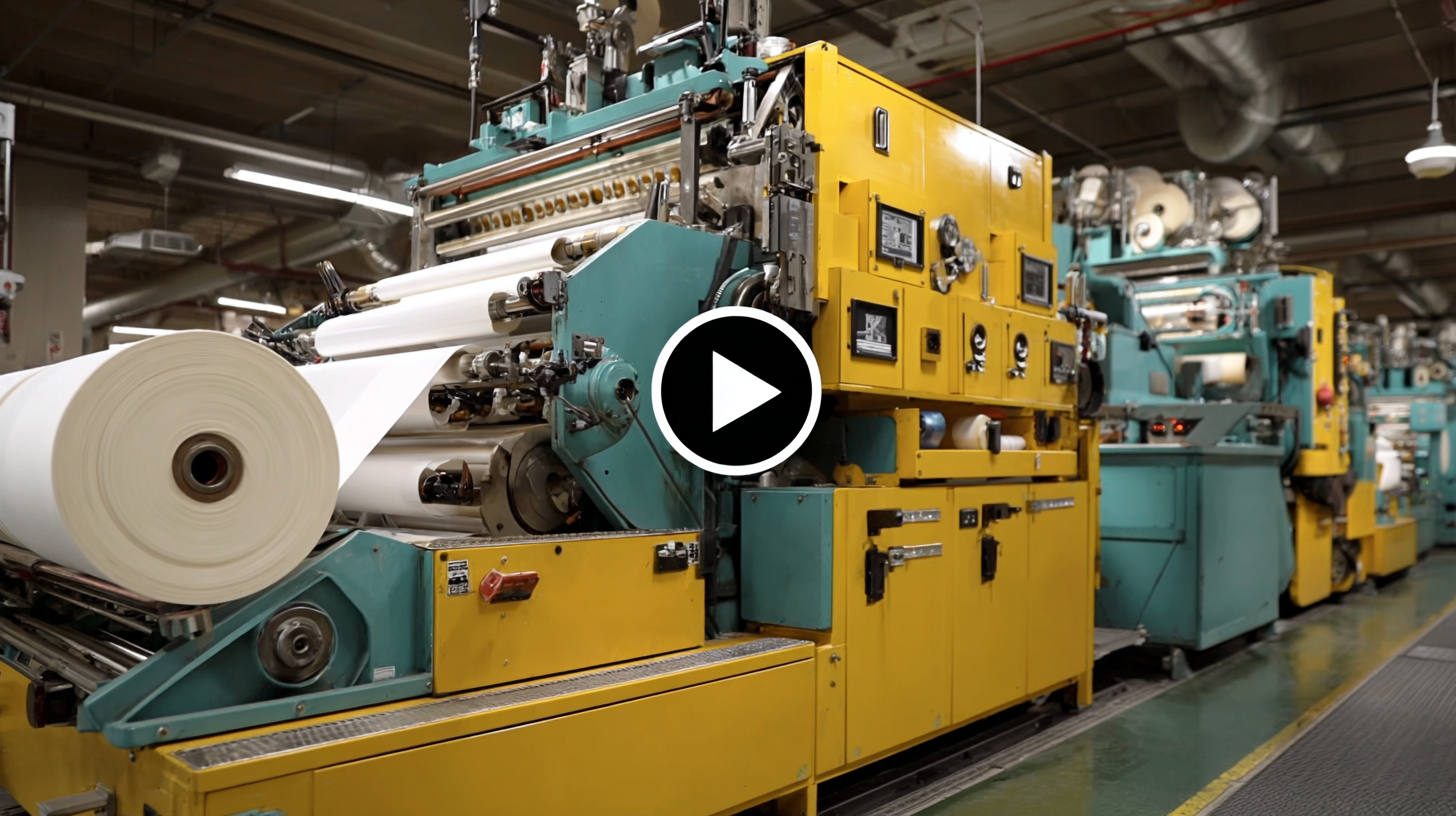

When it comes to selecting the best alpha winding machine for your production needs, it's crucial to understand the different types available on the market. Alpha winding machines play a significant role in various industries, particularly in the manufacturing of electrical machines. Each type of winding machine is designed to meet specific application requirements, offering unique features that cater to different production scenarios.

For instance, the 3-axis filament winding machines provide an efficient way to wind resin-impregnated fibers onto a rotating mandrel. This type of machine is ideal for producing high-performance composite parts used in automotive and aerospace applications. Additionally, the choice of winding topology can significantly impact the efficiency and performance of electrical machines. Optimized winding configurations can help reduce AC losses, making them essential for high-speed electric machines, which are becoming increasingly prevalent in the quest for power-dense solutions. By evaluating the capabilities and specialties of various alpha winding machines, manufacturers can enhance productivity and meet the growing demand for advanced electrical systems.

Evaluating Production Capacity to Match Your Needs

When selecting the best alpha winding machine for your production needs, evaluating your production capacity is paramount. According to a recent report by MarketsandMarkets, the global winding machine market is expected to grow at a CAGR of 4.5% from 2021 to 2026, reflecting a burgeoning demand for efficient production capabilities. Businesses must assess their current production scales and future growth projections to ensure that the chosen machine can handle both present demands and anticipated increases in output.

It's crucial to analyze key production metrics, such as cycles per minute and wire sizes accommodated by potential machines. For instance, a study by Mordor Intelligence indicates that machines capable of handling variable production speeds offer a competitive edge, allowing for adaptability in dynamic market environments. Additionally, factors like energy consumption and maintenance requirements play a crucial role in long-term operational efficiency. Choosing a winding machine that aligns with both existing and projected production capacities can significantly enhance productivity and reduce downtime, making it an essential investment for manufacturers aiming to stay ahead in a competitive market.

Ultimate Guide to Selecting the Best Alpha Winding Machine for Your Production Needs

| Machine Model | Max Winding Speed (RPM) | Production Capacity (Units/Hour) | Power Consumption (kW) | Weight (kg) |

|---|---|---|---|---|

| AWM-1000 | 150 | 100 | 5.5 | 250 |

| AWM-2000 | 200 | 200 | 7.5 | 300 |

| AWM-3000 | 250 | 300 | 10.0 | 400 |

| AWM-4000 | 300 | 400 | 12.0 | 500 |

Comparing Costs and Features of Top Alpha Winding Machines

When selecting the best Alpha winding machine for your production needs, comparing costs and features is crucial. A recent industry report highlights that the efficiency of winding machines can impact overall production costs by up to 20%. Machines with advanced automation features not only enhance productivity but also reduce error rates, leading to significant long-term savings. Features like programmable settings and real-time monitoring are increasingly regarded as essential for optimizing production output.

Tips: Always consider the return on investment (ROI) when evaluating different models. Look for machines that offer flexibility and scalability, as your production needs may evolve over time. It's also advisable to read customer reviews and case studies to understand how each machine performs in a real-world setting.

Notably, when comparing specific models of Alpha winding machines, metrics such as speed, ease of operation, and maintenance costs can help narrow down options. A survey by an independent research firm showed that machines with user-friendly interfaces reported a 30% decrease in training times for operators. Make sure to assess these features against your operational goals to ensure you select the most effective machine for your production environment.

Maintaining Optimal Performance: Tips for Omega Winding Equipment

When it comes to winding equipment, maintaining optimal performance is crucial for maximizing production efficiency. Omega winding machines, known for their reliability and precision, require regular maintenance to ensure they operate at peak performance. One effective tip is to frequently inspect and clean the components, including the winding heads and tensioning systems. This not only prevents buildup of debris that could affect operation but also helps in identifying any wear and tear that could lead to major breakdowns if left unaddressed.

Additionally, ensuring that operators are well-trained in the specific functionalities of Omega winding equipment contributes significantly to maintaining performance. Regular training sessions can help them understand the machine's capabilities, troubleshoot minor issues, and implement best practices, which collectively enhance the longevity and functionality of the equipment. Moreover, developing a scheduled maintenance plan that aligns with the production cycle can prevent unexpected downtimes and costly repairs, making the winding process more smooth and efficient.