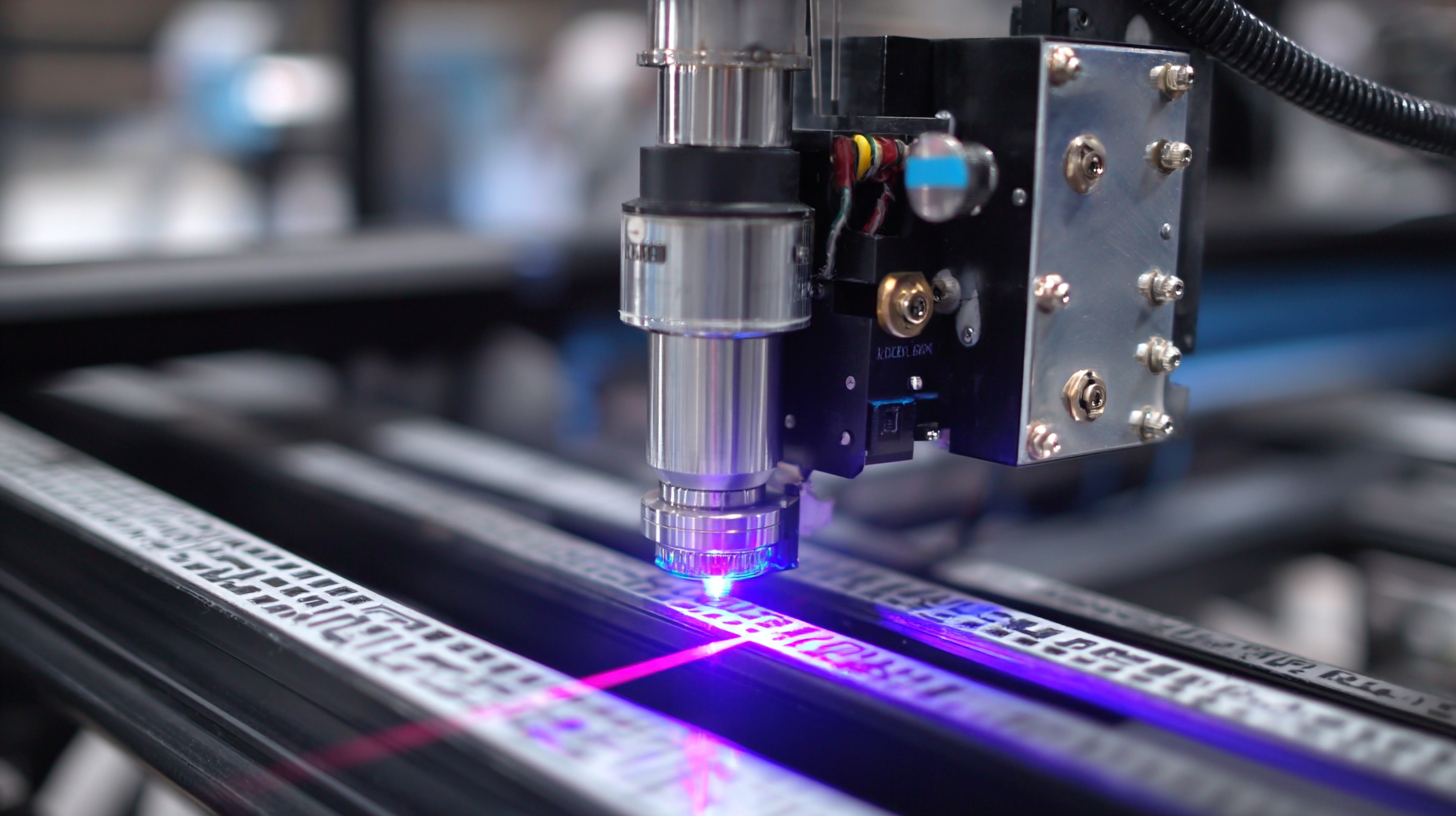

The Complete Guide to Choosing the Best Laser Marking Machine for Your Business

The rise of the manufacturing industry has led to an increased demand for advanced technologies that enhance productivity and precision. One such innovation is the Laser Marking Machine, which has become invaluable for businesses seeking to improve their branding and identification processes. According to a market research report by Grand View Research, the global laser marking market is projected to reach USD 5.92 billion by 2025, growing at a CAGR of 6.7%. This surge is attributed to the need for high-quality markings on products for traceability and compliance, along with the growing trend of customization across various sectors. However, selecting the right laser marking machine can be challenging due to the multitude of options available. This guide aims to illuminate the key considerations for choosing a reliable supplier, ensuring that your investment leads to optimal operational efficiency and superior product quality.

Understanding the Different Types of Laser Marking Machines Available Today

When it comes to selecting a laser marking machine for your business, understanding the different types available is crucial. Laser marking machines primarily fall into three categories: CO2 lasers, fiber lasers, and diode lasers. CO2 lasers are ideal for marking non-metallic materials like wood, glass, and plastics. Their ability to create detailed engravings makes them perfect for applications ranging from product branding to intricate design work.

On the other hand, fiber lasers are known for their efficiency in marking metals and some plastics. They offer high-speed operations with minimal maintenance, making them the preferred choice for industries such as electronics and automotive manufacturing. Fiber lasers provide excellent depth and clarity, ensuring that even the smallest details are reproduced accurately. Lastly, diode lasers are typically used for lighter-duty applications, offering an economical solution for businesses that require basic marking capabilities without the need for extensive versatility. By understanding these different types of laser marking machines, you can make an informed decision that best meets the specific needs of your business.

Key Factors to Consider When Choosing a Laser Marking Machine

When selecting a laser marking machine for your business, there are several key factors to consider that can significantly impact your operational efficiency and product quality. First, evaluate the machine’s capabilities regarding the materials you'll be processing. Different machines are designed to handle various substrates, such as metals, plastics, and wood, so ensuring compatibility with your materials is crucial. You should also assess the machine's power and speed, as these attributes directly influence the marking quality and production rate.

Another important aspect is the machine's ease of use and maintenance. Look for user-friendly interfaces that allow for quick setup and operation. A steep learning curve can lead to increased downtime and inefficiencies, so consider feedback from current users about their experiences. Moreover, don’t overlook the importance of after-sales support and availability of spare parts, as these can be vital for maintaining productivity in the long run. By carefully weighing these factors, you can make a more informed decision that aligns with your business needs.

The Comparison of Key Features of Laser Marking Machines

Evaluating the Performance and Reliability of Laser Marking Equipment

When selecting a laser marking machine for your business, evaluating the performance and reliability of the equipment is paramount. Performance metrics, such as marking speed, precision, and the types of materials the machine can handle, should be at the forefront of your decision-making process. Machines that offer high speed and accuracy can significantly enhance productivity while reducing waste. Additionally, consider the versatility of the marking system—whether it can execute different engraving tasks on various substrates, including metal, plastic, and wood, will determine how effectively it can meet your business needs.

Reliability is equally essential, as downtime for repairs can be costly and disrupt operations. Look for laser marking machines with a solid warranty and positive reviews regarding longevity and service support. Manufacturers that provide comprehensive training and customer service can make a difference in maintaining the equipment's performance over time. Investing in a reputable brand known for its reliability ensures that your business can operate smoothly and efficiently, ultimately leading to increased profitability and customer satisfaction.

Comparing Costs: Investing in Quality vs. Budget Options

When considering a laser marking machine for your business, one of the key factors to weigh is the cost versus the quality of the equipment. Budget options often draw immediate attention due to their lower initial price, but these machines can sometimes lack the durability and precision needed for professional applications. Investing in a higher-quality machine typically offers superior performance and longevity, translating to fewer operational issues and lower maintenance costs over time.

Tip: Before making a purchase, analyze your specific marking needs and production volume. If your business demands high precision and frequent usage, opting for a quality machine is a wise choice, even if it requires a larger upfront investment.

Another crucial aspect is to consider the long-term implications of your choice. While budget machines may suffice for minimal use or hobbyist applications, they might fall short under high-capacity demands. The difference in output quality can mean better customer satisfaction and, ultimately, repeat business.

Tip: Keep an eye on warranty and support options when evaluating machines. A reputable manufacturer often provides better service, which can save you time and money in the event of equipment issues.

Top Manufacturers of Laser Marking Machines for Global Export

When considering the purchase of a laser marking machine for your business, understanding the landscape of leading manufacturers is crucial. The laser processing equipment market is experiencing robust growth, projected to rise from $28.51 billion in 2025 to an impressive $64.39 billion by 2032, fueled by a compound annual growth rate (CAGR) of 12.3%. This expansion reflects the increasing demand for laser technologies across various industries, including automotive, electronics, and packaging.

Key manufacturers in the global market have established their presence through innovation and reliability, often excelling in high-power fiber and excimer laser sales. As businesses seek efficient and precise marking solutions, the reputation and performance of these manufacturers become vital considerations. Evaluating their product offerings enables companies to choose machines that not only meet their specific needs but also ensure longevity and scalability as their operational demands evolve. As you navigate this growing market, identifying and partnering with top manufacturers will play a significant role in enhancing your business's operational efficiency and product quality.

The Complete Guide to Choosing the Best Laser Marking Machine for Your Business

| Machine Type | Laser Type | Marking Speed (mm/s) | Laser Power (W) | Working Area (mm) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|---|

| CO2 Laser Marking Machine | CO2 | 600 | 40 | 300 x 200 | 50 | 3,500 |

| Fiber Laser Marking Machine | Fiber | 1200 | 20 | 110 x 110 | 30 | 4,000 |

| UV Laser Marking Machine | UV | 800 | 5 | 100 x 100 | 25 | 6,000 |

| Green Laser Marking Machine | Green | 1000 | 10 | 150 x 150 | 20 | 5,500 |