Top Strategies for Sourcing the Best Laser Marking Machine Globally

In today's highly competitive industrial landscape, sourcing the best Laser Marking Machine has become a crucial aspect for businesses aiming to enhance their manufacturing processes. As industries increasingly adopt advanced technologies to meet diverse marking needs, understanding the top strategies for procuring these machines on a global scale is essential. The right Laser Marking Machine not only improves product quality and efficiency but also plays a pivotal role in branding and traceability. This blog will explore the most effective approaches to identify and secure high-quality laser marking solutions that align with specific operational requirements, ensuring that your business stays ahead of the curve in innovation and productivity. Join us as we delve into the key factors to consider when sourcing these sophisticated machines, helping you make informed decisions that will benefit your operations in the long run.

Key Technical Specifications to Consider When Selecting a Laser Marking Machine

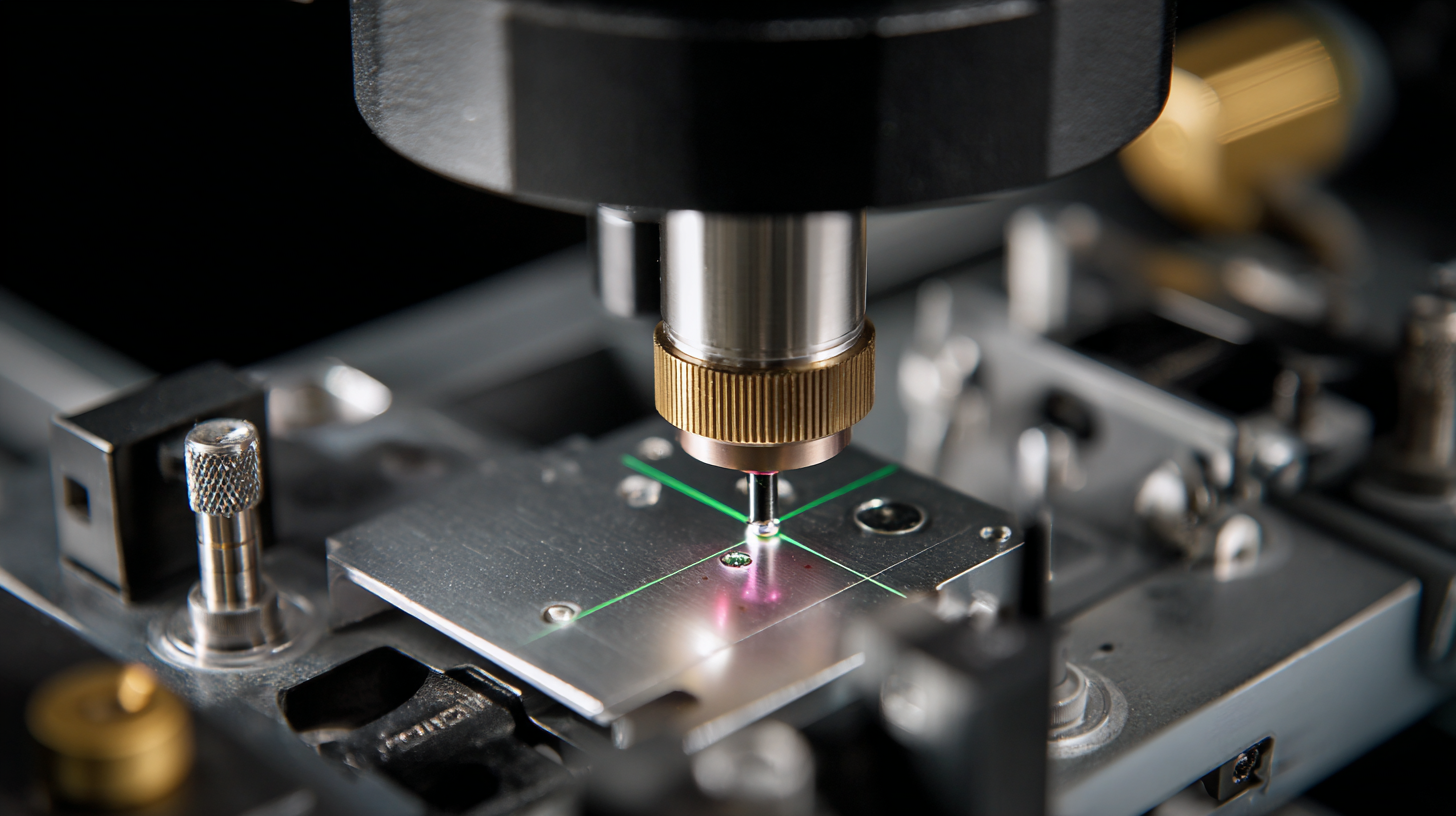

When selecting a laser marking machine, understanding the key technical specifications is crucial to ensuring you make the best choice for your application. One of the primary specifications to consider is the type of laser technology used in the machine, such as CO2, fiber, or YAG lasers. Each type has its advantages depending on the materials you plan to work with—fiber lasers, for example, are excellent for metals, whereas CO2 lasers are more versatile for non-metals.

Another important aspect to examine is the machine's marking speed and resolution. These factors determine how quickly and precisely the machine can engrave or mark surfaces. A higher marking speed is essential for production environments, while resolution affects the detail of the markings. Before making a decision, it is advisable to assess the workload and quality requirements of your projects to select a machine that aligns with your expectations.

Finally, consider the machine's compatibility with various software and its ease of integration into your existing workflow. A user-friendly interface and flexibility in software compatibility can significantly reduce training time and enhance operational efficiency. In my experience, investing time in understanding these technical specifications will pay off in the long run, ultimately leading to a more productive marking process.

Understanding Different Types of Laser Marking Technologies for Optimal Sourcing

When sourcing the best laser marking machine globally, understanding the different types of laser marking technologies is crucial. The most common laser types include fiber, CO2, and UV lasers, each offering unique advantages tailored to specific marking applications. According to the market research report by MarketsandMarkets, the global laser marking machine market is expected to grow from USD 3.2 billion in 2020 to USD 5.8 billion by 2025, reflecting a robust CAGR of 12.5%. This growth indicates the increasing demand for efficient and precise marking solutions across various industries, such as aerospace, automotive, and electronics.

Fiber lasers, recognized for their efficiency and speed, are particularly well-suited for marking metals, making them a popular choice among manufacturers. CO2 lasers, on the other hand, excel at marking non-metal materials such as plastics and wood, providing versatility for businesses engaged in diverse production lines. A report by Grand View Research highlights that the increasing adoption of laser marking technology for branding and traceability purposes significantly contributes to market expansion. By understanding these technologies, businesses can make informed sourcing decisions that align with their production requirements and enhance operational efficiency.

Evaluating Supplier Credibility: Ensuring Quality in Your Laser Marking Machines

When sourcing laser marking machines globally, evaluating supplier credibility is paramount to ensuring the quality and reliability of your investment. According to the International Laser Display Association, the global laser marking machine market is expected to grow at a CAGR of 6.2% from 2021 to 2028, emphasizing the need for companies to align with reputable suppliers in a competitive industry. A credible supplier not only offers advanced technology but also demonstrates robust after-sales support, which is crucial for maintaining operational efficiency and minimizing downtime.

To assess supplier credibility, businesses should scrutinize certifications and compliance standards. For instance, ISO 9001 certification is a fundamental indicator of quality management systems in manufacturing. Additionally, independent industry reports, such as those from Mordor Intelligence, underline the importance of suppliers having a proven track record of reliability, as failure rates for low-quality machines can reach up to 25% within the first year of operation. Engaging suppliers who invest in R&D and possess a portfolio of successful implementations can significantly mitigate risks and ensure that your laser marking machines meet the highest standards of performance and durability.

Cost Analysis: Balancing Budget and Quality in Laser Marking Equipment Sourcing

When sourcing laser marking machines, balancing budget and quality is crucial for any business looking to invest in this technology. Initially, it's important to establish a clear budget that accommodates not just the initial purchase price, but also ongoing costs such as maintenance, operation, and potential upgrades.

While it may be tempting to opt for the most affordable option, investing in higher-quality machines often pays off in the long run due to their reliability and lower downtime.

Moreover, conducting a thorough cost analysis requires evaluating the features and efficiency of various laser marking machines. Businesses should take the time to compare specifications across brands, focusing on aspects like mark speed, precision, and ease of use. Engaging with experienced suppliers and seeking out customer reviews can provide valuable insights into the performance of specific models.

Ultimately, finding the right balance between price and quality ensures that the chosen laser marking machine meets operational needs without breaking the bank.

Tips for Testing and Reviewing Laser Marking Machines Before Purchase

When considering the purchase of a laser marking machine, thorough testing and reviewing can significantly impact your investment. Start by examining the machine's specifications and capabilities. Look for features such as power settings, marking depth, and compatibility with various materials. A hands-on demonstration or trial run can provide insights into the machine's operational efficiency and ease of use. Pay attention to the quality of the markings produced—crisply etched designs and consistent depth are markers of a high-quality machine.

Next, evaluate the customer support and warranty options provided by manufacturers. A reliable supplier should offer extensive support, including installation guidance, maintenance training, and troubleshooting assistance. Reading customer reviews and testimonials can also help gauge the long-term performance and reliability of the machine. By incorporating these testing and review strategies, you can make an informed decision, ensuring that the laser marking machine you select meets your production needs effectively.